No doubt you are familiar with the term ‘Lean’. It’s become a popular terminology for change in today’s corporate culture.

No doubt you are familiar with the term ‘Lean’. It’s become a popular terminology for change in today’s corporate culture.

The creation of Lean Manufacturing is generally credited to Taiichi Ohno, a Toyota production executive, in an effort to reduce waste and improve quality.

And today, Lean Management techniques and principles are quite widely used throughout the Manufacturing industry. You may have heard Japanese terms like Kaizen, Kanban and Muda. This isn’t a secret key to unlock the mysteries of Lean, they simply mean Continuous Improvement, Pull systems and Non value-added work. These are terms used to convey the ideas of Lean thinking.

But we are often asked how a process improvement technique established specifically for manufacturing can be adapted for white collar work like Administration, Contact Centers and Document Management Centers.

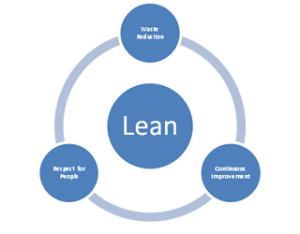

The truth is that ‘Lean’ is simply a way to reduce waste (often called Muda) using an approach that centers on creating value for your customers. The Lean approach centers around 5 categories:

• Value

• Value Stream

• Flow

• Pull

• Perfection

One of the most common issues that we see with our clients, is the amount of times we hear, “I don’t know why I do that” or “we’ve always done it this way”. Sometimes, it takes someone from the outside to question the status quo.

Lean Consultants spend time observing your key processes to determine if they are set up for maximum efficiency. We begin by developing simple, customer-focused process maps and work with your staff to develop a leaner, more efficient process and finally gain approval through your in-house compliance process.

Some customers are concerned that their industry is heavily regulated and process changes are frowned upon, but with our approach, we take you with us every step of the way.